Blog

7 Essential Features of the Top Grease Interceptors You Should Know

In the ever-evolving landscape of environmental sustainability and wastewater management, grease interceptors have emerged as critical components for commercial kitchens and food establishments. According to a report by the U.S. Environmental Protection Agency, improper disposal of fats, oils, and grease (FOG) contributes significantly to municipal sewer blockages, leading to costly repairs and environmental hazards. In fact, it is estimated that FOG causes over 47% of all sewer backups in the United States, highlighting the urgent necessity for effective grease management solutions.

Understanding the essential features of grease interceptors is vital for ensuring compliance with local regulations and maintaining operational efficiency. This blog will explore the seven key characteristics that define the top grease interceptors, providing operators with insights to select the most appropriate systems for their needs while contributing to a cleaner, more sustainable future.

Key Design Elements That Enhance Grease Interceptor Efficiency

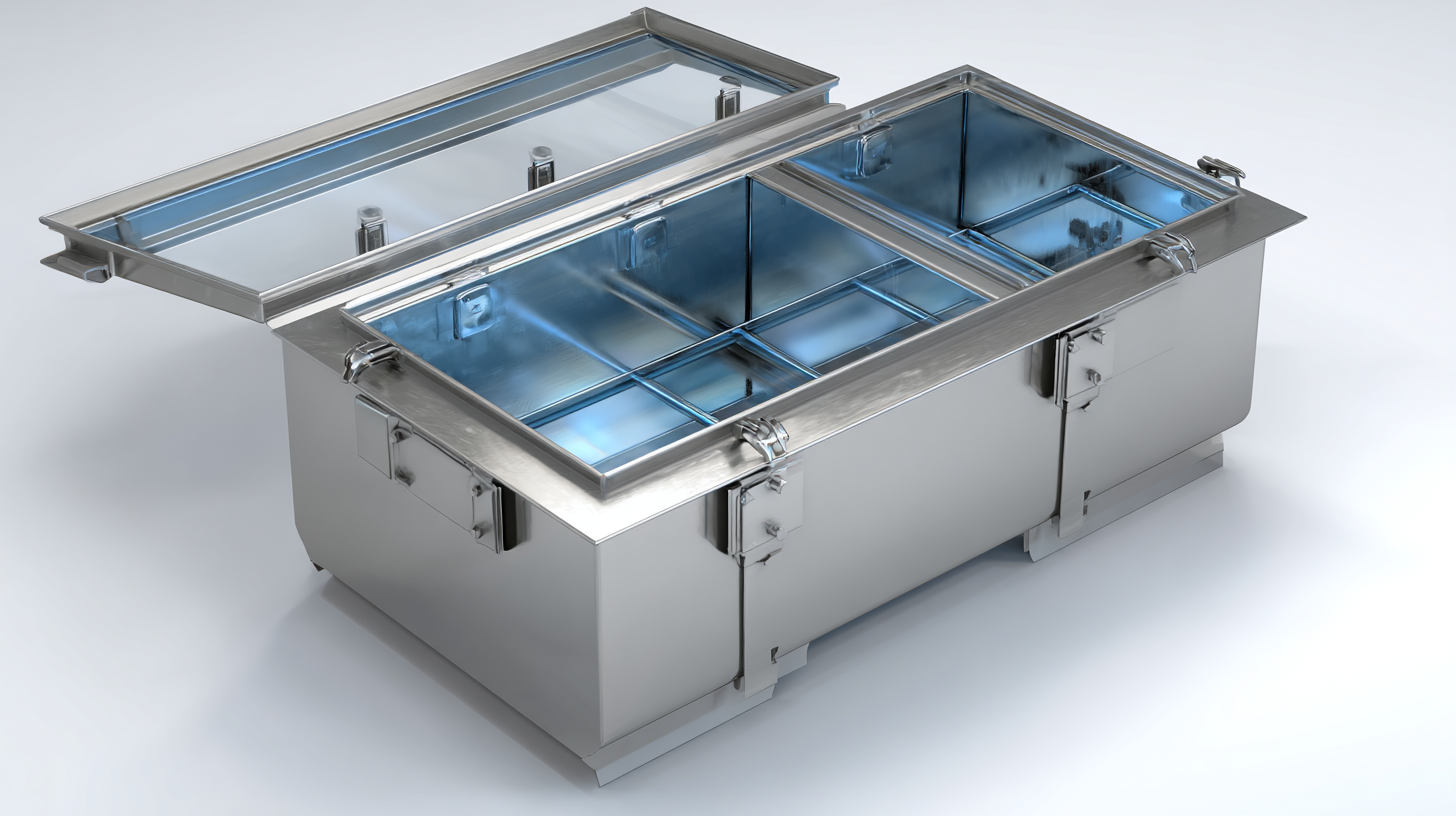

When selecting the best grease interceptors, understanding key design elements that enhance their efficiency is crucial. One essential feature is the interceptor's size and capacity. A well-sized unit can accommodate the volume of wastewater generated by a kitchen while effectively separating grease from water. This ensures optimal flow and reduces the risk of overflow or backflow, which can lead to costly plumbing issues and health code violations.

Another critical design aspect is the use of advanced baffle systems. These baffles play a vital role in directing the flow of wastewater, allowing for improved separation of grease and solids. A well-designed baffle system helps to maintain a consistent water level, maximizing detention time where grease can rise to the surface for easier removal. Additionally, easy access points for maintenance and cleaning are imperative. Regular maintenance not only prolongs the lifespan of the grease interceptor but also ensures that it continues to perform at peak efficiency, preventing any potential environmental hazards. Investing in interceptors with these design features top of mind will significantly enhance grease management practices in any commercial kitchen.

7 Essential Features of the Top Grease Interceptors You Should Know

| Feature | Description | Benefits |

|---|---|---|

| High Capacity | Designed to handle large volumes of grease and food debris. | Prevents frequent maintenance and reduces the risk of clogs. |

| Effective Grease Retention | Utilizes baffles and other design elements to retain grease efficiently. | Enhances removal efficiency and maintains optimal flow rates. |

| Easy Access for Cleaning | Features access ports and removable components for simple maintenance. | Saves time and labor costs associated with cleaning. |

| Odor Control | Incorporates technologies to minimize odors during operation. | Improves overall hygiene and comfort in the kitchen environment. |

| Durable Construction | Made from corrosion-resistant materials for long-lasting use. | Reduces replacement frequency and ensures reliability. |

| Compact Design | Optimized for installation in tight spaces without sacrificing performance. | Maximizes use of space in commercial kitchens. |

| Regulatory Compliance | Designed to meet local regulatory standards and health codes. | Ensures smooth operation without legal hassles. |

Understanding the Role of Sizing in Grease Interceptor Performance

When it comes to grease interceptors, proper sizing plays a pivotal role in their overall performance. According to industry reports, an insufficiently sized interceptor can result in frequent clogs and odor issues, with maintenance costs potentially soaring by 20-25%. The aim is to ensure that the interceptor can effectively handle the volume of fats, oils, and grease (FOG) generated by your establishment, particularly during peak operational hours. For instance, the Environmental Protection Agency (EPA) recommends that food service establishments assess their waste production levels to select an interceptor that accommodates their specific needs.

Tip: Regularly monitor the grease levels in your interceptor. Keeping track of these levels assists in determining when to schedule maintenance, which can significantly improve performance and reduce the risk of overflows.

Selecting the right grease interceptor not only enhances operational efficiency but also contributes to environmental sustainability. Studies indicate that properly sized interceptors can reduce FOG discharge into sewage systems by 90%, helping to prevent costly municipal sewer system blockages and associated fees. Furthermore, ensuring the interceptor meets local regulations can save establishments from fines due to non-compliance.

Tip: Work with a professional to size your grease interceptor correctly. This expertise can lead to long-term savings by ensuring your system runs smoothly and adheres to local regulations.

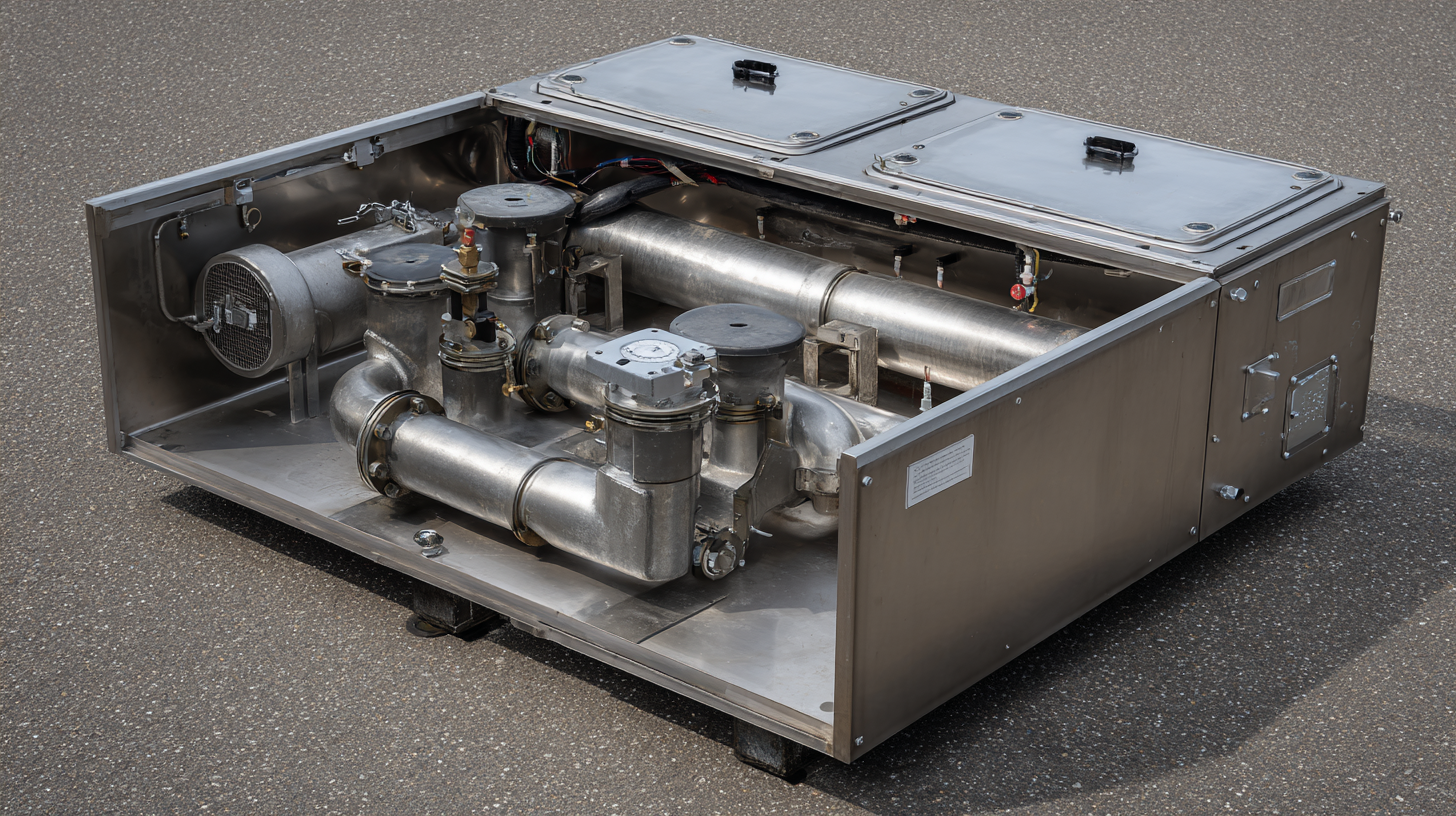

Innovative Materials and Their Impact on Grease Interceptor Longevity

Innovative materials play a pivotal role in enhancing the longevity and efficiency of grease interceptors in today's culinary and industrial settings. As operators look for solutions that promise durability and superior performance, advancements in composite materials offer significant benefits. These materials not only improve resistance to corrosion and thermal stress but also contribute to better overall functionality of grease interceptors, leading to longer service life and reduced maintenance costs.

The current trends in thermal interface materials highlight a growing emphasis on sustainable and high-performance solutions. For example, bio-based materials are being increasingly adopted, offering a more environmentally friendly footprint while ensuring effective barrier qualities. This shift aligns with ongoing developments across various industries, including electric vehicles and renewable energy, where efficient thermal management is essential. By adopting these innovative materials, grease interceptors can better withstand the harsh conditions they face, ultimately fulfilling the increasing demand for reliable and high-capacity systems in managing grease disposal effectively.

Importance of Maintenance Access for Optimal Grease Management

When it comes to managing grease in commercial kitchens, the importance of maintenance access for grease interceptors cannot be overstated. These essential devices help prevent grease from entering the drainage system, but without proper access for maintenance, their effectiveness diminishes significantly. Regular maintenance is crucial to ensure that grease interceptors function optimally, avoiding costly plumbing issues and health code violations.

Tips for ensuring easy maintenance access include strategically placing grease interceptors in accessible locations. This not only facilitates routine inspections and cleanings but also enables quick response times in case of emergencies. Additionally, labeling access points clearly can help staff and maintenance crews locate necessary areas quickly, reducing downtime and disruption during service hours.

Another important aspect is to keep maintenance records organized and readily available. Documenting service dates, inspection results, and any necessary repairs can help maintain a proactive maintenance schedule. Incorporating these practices into your grease management strategy will contribute to the longevity and efficiency of your grease interceptors, ensuring they serve their purpose without interruption.

Regulatory Compliance Features in Modern Grease Interceptors

In today's foodservice industry, regulatory compliance is a critical consideration when selecting grease interceptors. Modern grease interceptors are designed to meet stringent environmental regulations that aim to prevent grease and fats from entering the wastewater system. One of the primary features to look for is a robust capacity to handle varying flow rates while efficiently separating grease from wastewater. This ensures that businesses remain compliant with local wastewater management regulations and avoid potential fines or shutdowns.

Another essential compliance feature is the inclusion of an easily accessible monitoring system. This allows operators to check the interceptor's performance regularly and maintain it accordingly, ensuring it functions effectively. These systems often include readable indicators for grease levels and maintenance needs, allowing staff to stay proactive in their compliance efforts.

Additionally, many modern interceptors incorporate eco-friendly materials and designs, aligning with sustainability initiatives while still fulfilling regulatory requirements. With the right features, grease interceptors can play a vital role in both compliance and environmental stewardship for food establishments.

Request a Quote

Fill out the form below and one of our specialists will contact you to discuss your questions and needs.