Blog

What is a Geomembrane Welding Machine and How Does It Work?

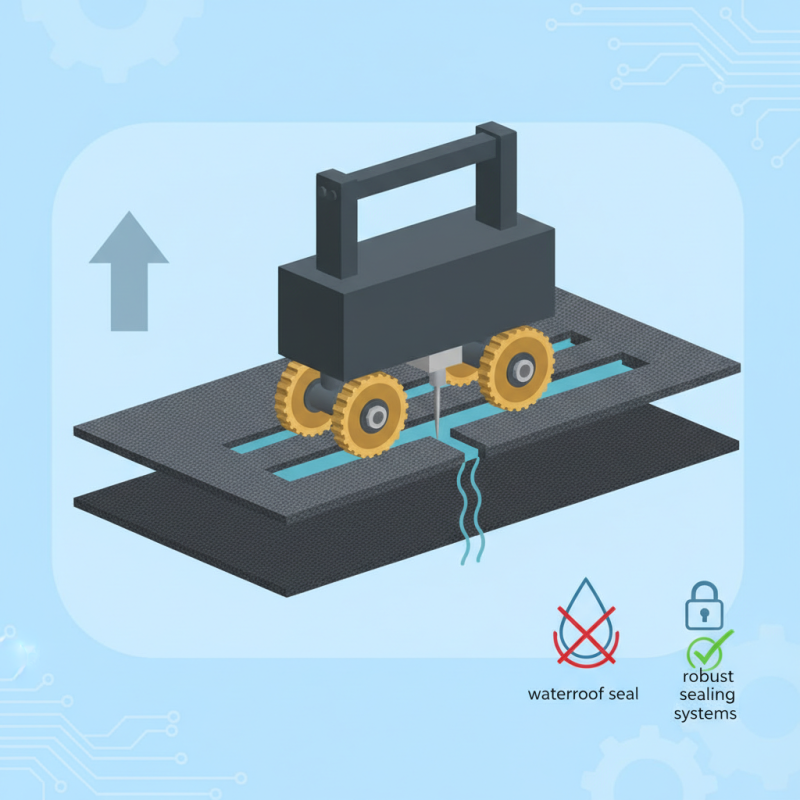

A geomembrane welding machine is vital in many industries. It plays a crucial role in constructing containment systems. These machines are designed to join geomembrane materials effectively and provide strong, waterproof seals.

Understanding how a geomembrane welding machine works is essential for various applications. This machine often uses heat or friction to bond materials. In projects like landfill liners or water reservoirs, a reliable weld is critical. Poorly made seams can lead to leaks, which can be costly and damaging.

The technology behind these machines may seem complex, but their operation is straightforward. Users must be trained to operate them correctly. Mistakes during the welding process can lead to significant problems. Ensuring consistent quality is an ongoing challenge. As the demand for robust sealing systems grows, continuous improvement in geomembrane welding technology remains necessary.

What is a Geomembrane Welding Machine: Definition and Purpose

A geomembrane welding machine is essential in installing geomembranes for various applications. These applications include landfill liners, agricultural ponds, and water containment systems. The primary purpose of these machines is to create strong, durable seams between geomembrane sheets, ensuring that liquids do not leak.

According to a report by Grand View Research, the geomembrane market is expected to reach $3.13 billion by 2025. This indicates a growing demand for reliable welding machines. A good seam can withstand environmental stresses, and a weak seam may lead to failures. Poor welding practices can result in significant financial losses.

The welding process involves heating the edges of geomembranes and pressing them together. It requires precision. Too much heat can damage the materials, while too little may lead to weak joints. Operators need to undergo proper training. Even slight errors can compromise the integrity of the installation. It's clear that while technology advances, human skill remains crucial in this field.

Key Components of a Geomembrane Welding Machine Explained

A geomembrane welding machine is essential for the construction industry. It's used to join geomembrane materials, often utilized in landfills and reservoirs. Understanding its key components helps in grasping how it operates efficiently.

The machine typically includes a heating element. This element generates heat, allowing the geomembrane sheets to fuse together. Temperature control is vital. Too high can damage materials; too low may result in weak seams. A recent report by the Geosynthetic Research Institute highlights that improper welding can reduce seam strength by 30%. This emphasizes the precision required in the process.

Another crucial component is the pressure system. This ensures consistent contact between the geomembranes during welding. Some machines use roller systems to apply pressure evenly. This promotes better fusion. Poorly applied pressure often leads to leaks later on. Studies indicate that leaks are responsible for 40% of environmental failures in geomembrane applications. Such figures demonstrate the importance of using high-quality welding machines for successful projects.

Welding Techniques Used in Geomembrane Applications

Geomembrane welding is crucial in various industries. It ensures waterproofing and containment for landfills, reservoirs, and mining operations. Key techniques include hot air welding, extrusion welding, and solvent welding.

Hot air welding is the most common method. It uses heated air to soften the geomembrane edges, which are then pressed together. According to a recent industry report, 70% of geomembrane installations utilize this technique. It offers strong seams and is versatile for different materials.

Extrusion welding involves applying molten material to join seams. While it allows for repairs on-site, it demands precise control of temperature and speed. Data shows that improper welding can lead to failures, costing projects significantly.

Tip: Always conduct quality checks post-welding. Regularly inspect seams for weaknesses. Good training is vital for machine operators.

Understanding these techniques helps ensure project success. Not every method is suitable for all applications, highlighting the need for careful selection. Reflect on past projects to assess which techniques were effective. This approach leads to better future outcomes.

Industry Standards and Specifications for Geomembrane Welding

Geomembrane welding is a crucial process in various industries, especially in construction and environmental projects. Industry standards play a significant role in ensuring that this process is effective and reliable. These standards outline the specifications for materials, machinery, and procedures to guarantee quality.

For geomembrane welding, techniques such as hot wedge welding and extrusion welding are common. Each method has specific requirements. For instance, the welding temperature, speed, and pressure must be carefully controlled. Improper settings can lead to weak seams that fail under stress. These failures can result in serious problems, including water leakage and contamination.

Additionally, regular inspections are vital. They ensure that the welded seams meet the prescribed standards. It's essential to keep updated with the latest specifications and technological advancements. The industry is consistently evolving. This can sometimes leave workers questioning their methods. New approaches might yield better results, but adapting to these changes takes time and effort.

What is a Geomembrane Welding Machine and How Does It Work? - Industry Standards and Specifications for Geomembrane Welding

| Specification | Description | Standard |

|---|---|---|

| Welding Method | Hot Air, Extrusion, or Electrofusion | ASTM D Weld 12 |

| Material Thickness | 0.5 mm to 3.0 mm | GSI & IGS |

| Temperature Range | 450°F to 950°F | ISO 9001 |

| Welding Speed | 0.5 m/min to 3.0 m/min | ASTM D 6392 |

| Pressure | 0.5 to 3.0 bar | BS EN 12326 |

Advantages of Using Geomembrane Welding Machines in Construction

Geomembrane welding machines play a crucial role in construction projects, especially for containment and lining applications. These machines use heat and pressure to fuse geomembranes, providing a strong, watertight seal. The process ensures that the materials bond properly, reducing the risk of leaks in landfills, ponds, and other environments.

One significant advantage of using these machines is enhanced durability. Industry reports suggest that well-welded geomembranes can last over 30 years in harsh conditions. This longevity minimizes maintenance needs and reduces long-term costs. Additionally, the use of automation in welding machines can increase accuracy and efficiency. According to a recent study, automated welding can boost productivity by up to 40% compared to manual methods.

However, mistakes can occur during the welding process. Inadequate temperature control or improper alignment can lead to weak seams. Regular training and monitoring are essential, but these aspects are often overlooked. Even small errors can jeopardize the integrity of a project. Investing in high-quality machines and ongoing staff education could mitigate these risks. Ignoring these elements may result in costly repairs down the line, highlighting the need for thorough preparation in every project.

Article Source:

Request a Quote

Fill out the form below and one of our specialists will contact you to discuss your questions and needs.