Blog

What is a Grease Interceptor and How Does It Work?

In the food service industry, grease interceptors play a crucial role. These devices prevent fats, oils, and greases from entering wastewater systems. According to the Environmental Protection Agency (EPA), approximately 30% of sewer problems are linked to grease buildup. The importance of grease interceptors cannot be overstated, as they protect both our environment and infrastructure.

Dr. Emily Sanford, a renowned expert in wastewater management, stated, "Grease interceptors are essential for maintaining a clean and efficient plumbing system." Her insights highlight the responsibility of restaurants to manage waste effectively. Yet, not all establishments comply with regulations regarding grease interceptors.

This oversight can lead to costly repairs and environmental damage. Many facilities underestimate the impact of proper maintenance. Regularly servicing grease interceptors ensures their effectiveness. Ignoring this duty can result in significant issues. The grease interceptors industry faces challenges, but awareness is growing. Understanding the significance of these devices is crucial for sustainable operations in the food service sector.

What is a Grease Interceptor?

A grease interceptor is a crucial component for restaurants and food service establishments. It captures fats, oils, and grease, preventing them from entering the wastewater system. These materials can clog pipes and lead to costly repairs. By intercepting these substances, businesses help maintain a smooth flow in the plumbing system.

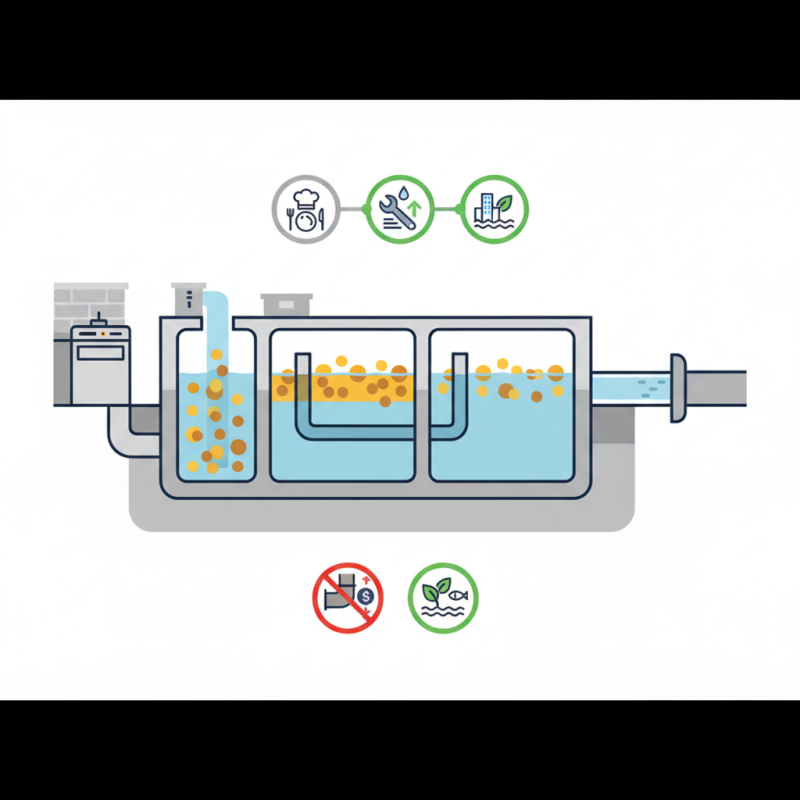

Typically, grease interceptors are installed in the kitchen. They function by slowing down the flow of wastewater, allowing grease to rise to the surface. The solid waste settles at the bottom. This separation process is vital to keep the pipes clear. Regular maintenance is essential, as accumulations can affect performance. Neglecting the cleaning can lead to blockages.

While grease interceptors are effective, some may overlook their importance. A dirty interceptor can cause foul odors and contribute to plumbing issues. Businesses should regularly inspect and empty their units. Awareness and proactive management can save time and money. In the end, these systems are not just a responsibility; they are part of operating a successful kitchen.

What is a Grease Interceptor and How Does It Work?

| Feature | Description | Importance |

|---|---|---|

| Purpose | A grease interceptor is designed to capture and separate grease and solids from wastewater before it enters the sewage system. | Prevents clogging of sewer lines and reduces maintenance costs. |

| Components | Typically includes an inlet, a separation chamber, and an outlet, often made of concrete or plastic. | Simple design allows for effective separation of grease and solid materials. |

| Operation | Wastes enter the interceptor, where grease rises to the top and solids settle at the bottom. | Ensures that only clean water exits the interceptor into the sewer system. |

| Maintenance | Regularly requires pumping and cleaning to remove accumulated grease and solids. | Maintenance is crucial to ensure proper function and prevent overflow. |

| Regulations | Many local laws require businesses, especially restaurants, to install and maintain grease interceptors. | Compliance prevents legal issues and protects municipal sewage systems. |

The Purpose of a Grease Interceptor in Waste Management

A grease interceptor is essential in waste management, especially in commercial kitchens. These devices capture fats, oils, and grease (FOG) before they enter the sewer system. When cooking, these substances often accumulate, leading to clogs and backups. The interceptor works by slowing down wastewater flow, allowing FOG to rise to the top, where it can be accessed and removed.

Preventing FOG from reaching the municipal sewer system is crucial. This process not only protects the pipes but also the local environment. Without grease interceptors, grease can cause significant harm, such as pollution and damage to water treatment facilities. Regular maintenance is necessary, as buildup can occur quickly, leading to inefficiencies. It's not enough to install these devices; consistent checks are vital for optimal function.

Many overlook this aspect, leading to failures that could easily be prevented. Grease interceptors are a key part of responsible waste management, reflecting the importance of proactive measures in maintaining our infrastructure.

How Does a Grease Interceptor Function?

A grease interceptor is a device designed to capture grease and food solids from wastewater. It plays a crucial role in preventing these materials from entering the sewage system. The function of a grease interceptor is based on a simple principle: separation. Grease is lighter than water. When wastewater flows into the interceptor, the grease rises to the top while solids settle at the bottom.

Inside the interceptor, various chambers help to manage the flow of water. As wastewater enters, it slows down, allowing grease to float up and solids to sink. This separation prevents blockages in plumbing. The grease is trapped and should be removed regularly. If not, the interceptor can become ineffective and lead to costly plumbing issues.

Over time, the grease can build up, creating a more serious problem. The interior of the interceptor requires inspection and maintenance. Neglecting this task can lead to odors and system failures. It's essential to establish a regular cleaning schedule. A functioning grease interceptor is vital for any establishment serving food. However, it demands attention and awareness. Remembering to check it regularly can save time and money in the long run.

Key Components of a Grease Interceptor System

A grease interceptor is a vital system in commercial kitchens. It captures and separates fats, oils, and greases from wastewater. This prevents blockages in plumbing and helps protect the environment. Understanding its components is key to effective operation.

The primary components of a grease interceptor include the tank, baffles, and outlet pipe. The tank collects wastewater from kitchens. As the wastewater enters, heavier solids settle at the bottom. Lighter materials, like grease, float to the top. Baffles help keep these layers separate. Regular cleaning is needed to maintain efficiency.

Sometimes, grease interceptors can be overlooked in maintenance schedules. Failure to clean can lead to clogs and unpleasant odors. Operators might underestimate how often inspection is needed. Ideally, you should check it every month. Small problems can lead to big issues if ignored. It's essential to stay vigilant.

Maintenance and Care for Grease Interceptors

Grease interceptors are essential for any commercial kitchen. They trap fats, oils, and grease before they enter the plumbing system. Regular maintenance is crucial for their efficient operation. This often involves checking the interceptor for buildup. Too much buildup can lead to clogs and unpleasant odors.

Cleaning a grease interceptor requires more than just a quick rinse. It should be done at least once a month. Inspecting the inlet and outlet pipes is important too. These areas can collect debris. If left unattended, they can cause serious issues. Remember, grease can harden over time, making it harder to remove.

Staff training is also critical. All kitchen personnel should know how to use the interceptor properly. They should understand the importance of minimizing grease waste. Over time, neglecting to maintain the unit can become costly. Routine checks can save money in the long run. It's all about being proactive and aware of what goes down the drain.

Related Posts

-

Essential Insights for Understanding Septic Services and Their Benefits

-

How to Embrace 2025 Trends in Grease Interceptor Technology for Optimal Efficiency

-

How to Effectively Maintain Your Septic System for Optimal Performance

-

What is Liquid Waste? Understanding Types, Management, and Solutions

-

Unlocking Quality Suppliers: The Definitive Guide to Sourcing County Waste Solutions Globally

-

Navigating the Best Liquid Waste Solutions in 2025 for Industry Leaders

Request a Quote

Fill out the form below and one of our specialists will contact you to discuss your questions and needs.